Mechanical Engineering Capstone

gifs may take a moment to load...

gifs may take a moment to load...

For the engineering capstone project, I was placed on a team of four graduating Mechanical Engineering students. In this project, the team was tasked with creating a better solution to unloading coffee bags from a trailer.

<A current design can be seen here>

The current design posed many issues, the most notable being the cost and time it took to unload. The team was tasked with creating a new alternative that would be cheaper (under $100,000), require few operators, and increase efficiency.

Courtesy: Copal Handling Systems on Youtube https://youtu.be/n1rdDZCJ3s0

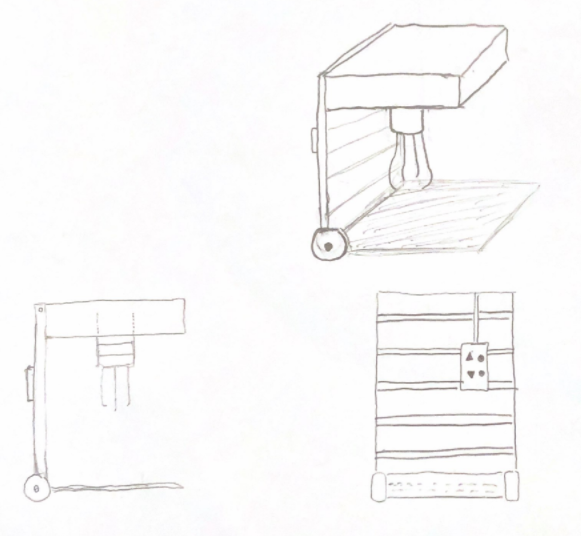

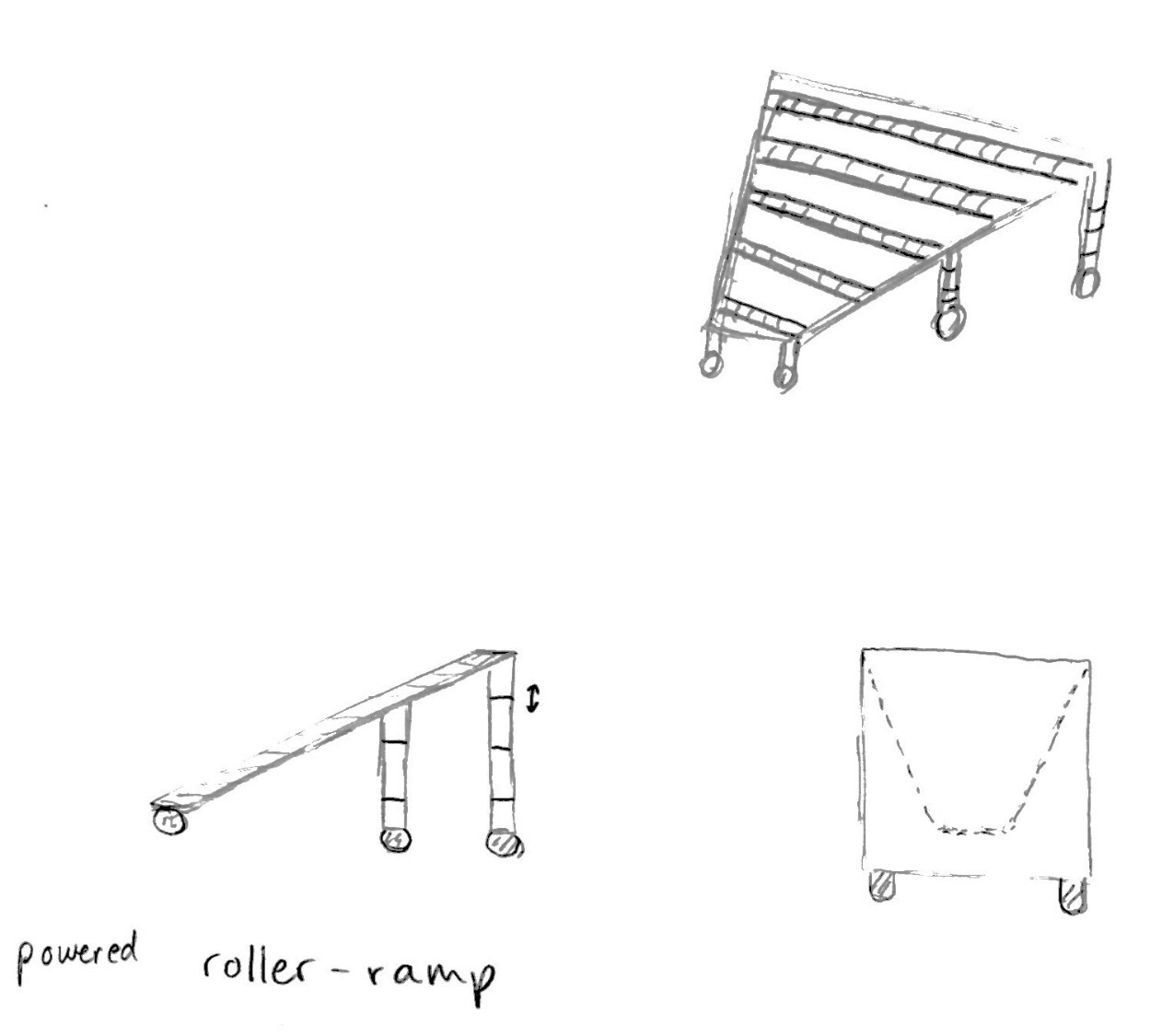

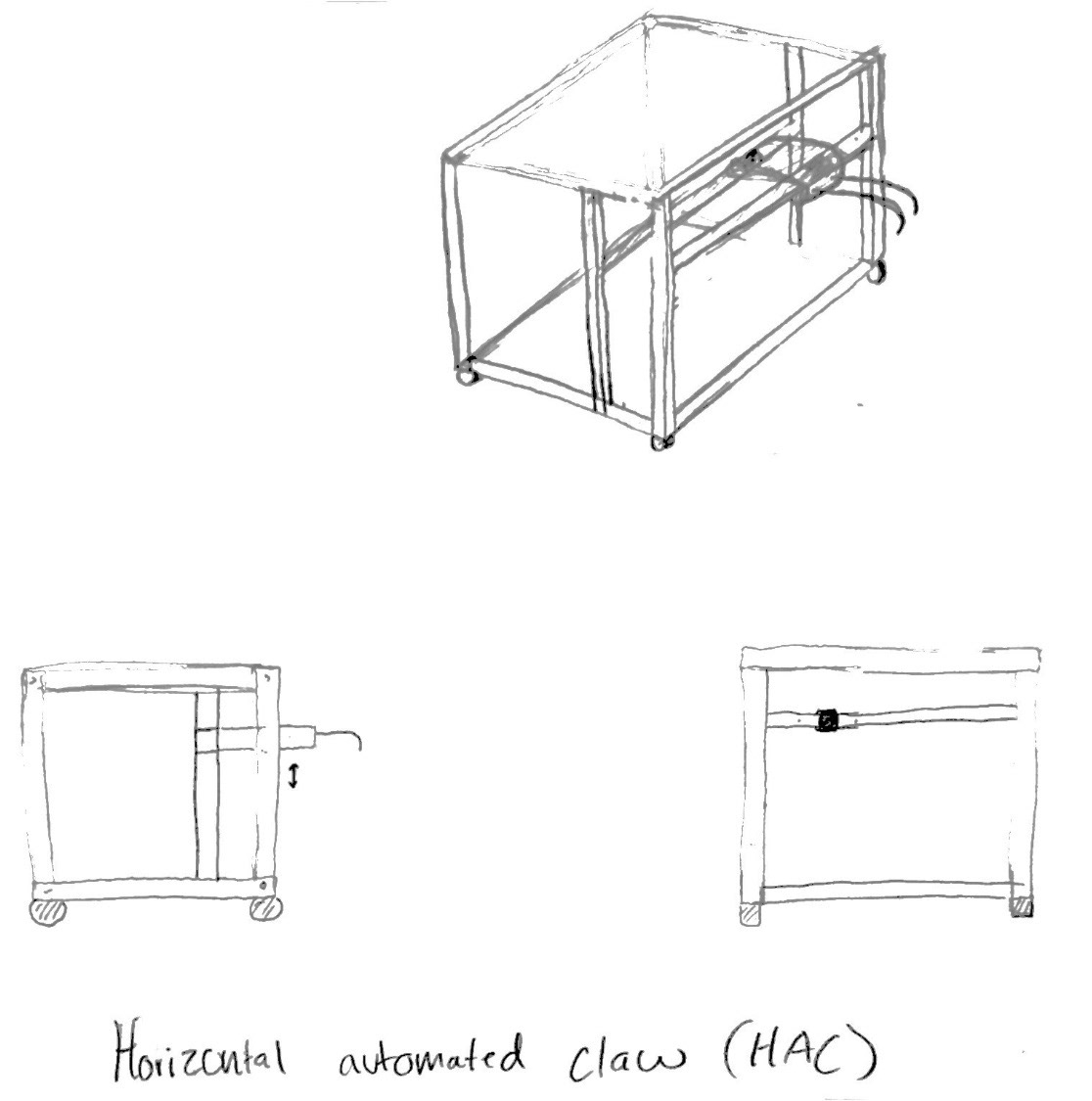

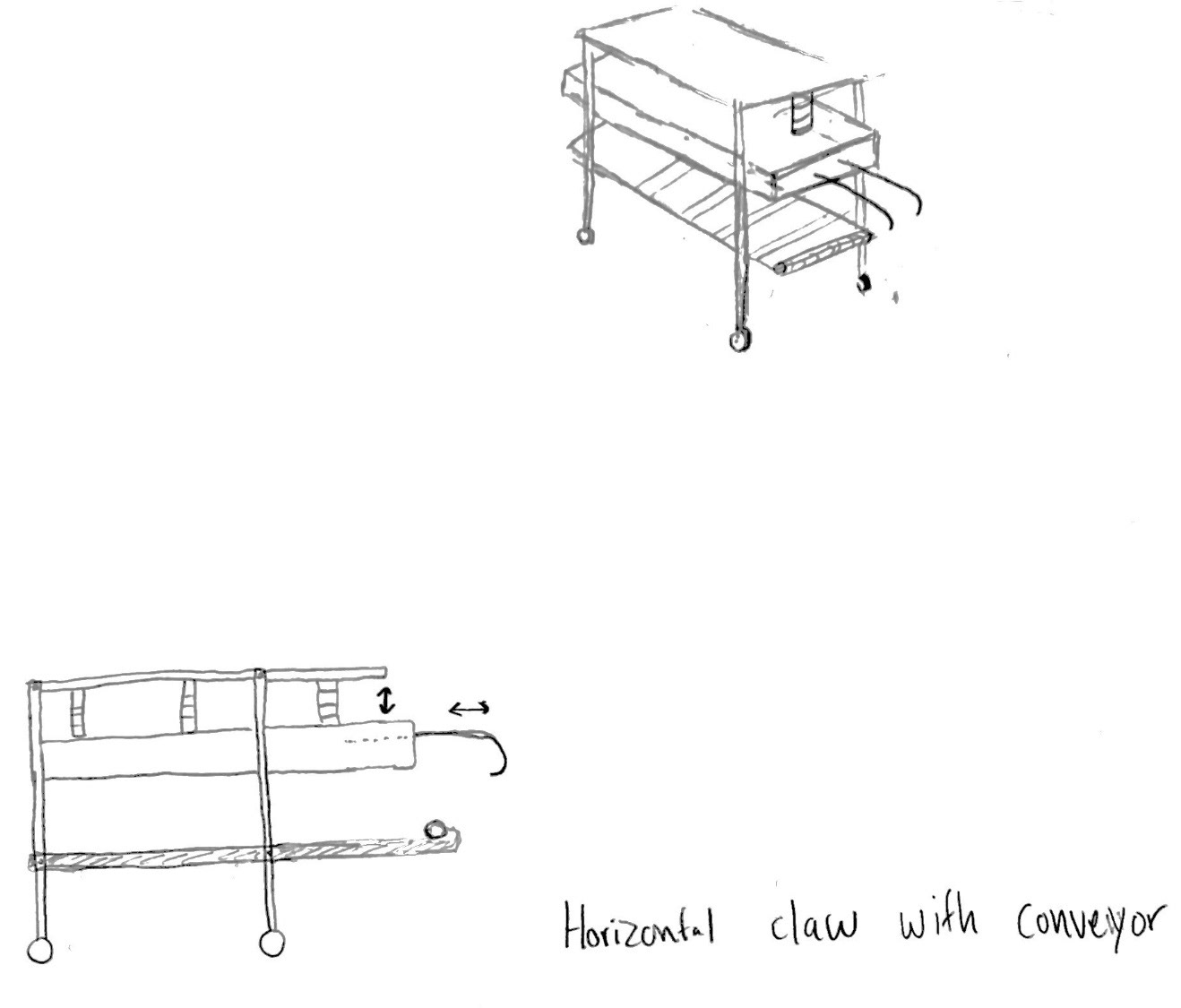

The team collaborated and brainstormed different ideas. I illustrated these ideas for an initial showing to the company sponsoring the project.

After feedback, the team got to work creating a new machine that would meet the criteria already listed.

The machine was split between three different sub-assemblies between three students. Spencer was tasked with creating the frame sub-assembly, and all of the parts of the frame are showcased above.

As Spencer built the frame, a few issues were presented. Per the design the team had chosen, the chassis had to fit inside of a trailer to work. This proved difficult to build a frame that housed all the needed parts within the space requirement.

The wheels were connected via a coupling rod, powered by a singluar driving wheel for each side. The power to go, stop, and reverse would all be controlled by two central motors.

The threaded rod with two supporting rods allowed the arm and conveyor to move in the z-direction by two other motors.

The team created a performance metrics script that helped to estimate the time it would take to unload a 20-foot and 40-foot trailer. The conclusion was that this machine would unload around 19 minutes or a 34% decrease of the target.

In the end, the sponsored company believed the team had come up with a viable solution to their issue. The biggest concern was the number of parts that would potentially be needing repair as the machine takes wear and tear.

Programs and Practices used:

Sketching, Solidworks, PhotoView, Animation